Granite is a durable and versatile natural stone commonly used in construction and landscaping. One common question is whether granite can be crushed for various purposes. Let’s explore the possibilities.

Natural Strength of Granite

Granite is renowned for its strength and durability. It is formed from molten magma that cools and solidifies deep within the earth’s crust. This natural process results in a dense and hard stone that can withstand heavy loads and harsh environmental conditions.

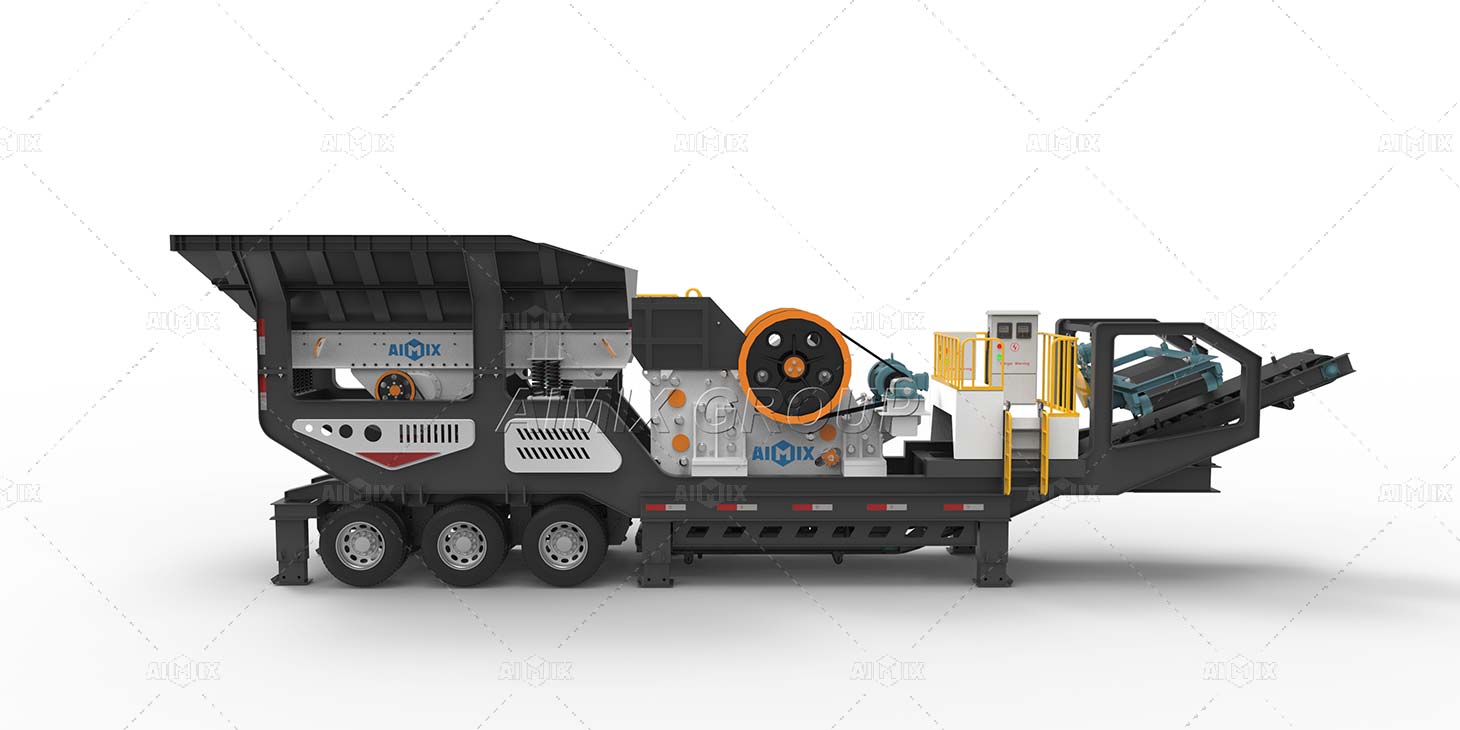

Crushing Process

While granite is incredibly strong, it can indeed be crushed with the right crushing and screening plant and techniques. The crushing process involves using specialized machinery to break down large granite rocks into smaller pieces or aggregates.

Uses of Crushed Granite

Crushed granite has various applications in construction, landscaping, and road-building projects. Some common uses include:

- Aggregate for concrete and asphalt production

- Base material for roads, driveways, and pathways

- Fill material in retaining walls and drainage systems

- Decorative gravel for landscaping and garden pathways

Crushing Equipment

Several types of crushing equipment can be used to crush granite:

- Jaw Crusher: Ideal for primary crushing, jaw crushers exert force to break granite into smaller pieces.

- Impact Crusher: These granite crushers use impact force to crush granite, producing uniform-shaped aggregates.

- Cone Crusher: Suitable for secondary and tertiary crushing, cone crushers produce finely crushed granite.

Notes on the Selection of an Additional Portion

When choosing an additional portion for a project or task, it’s essential to consider various factors to ensure the best outcome. Below are some key notes to guide your selection process.

Identify Specific Needs

Before selecting an additional portion, clearly define the specific requirements of your project or task. Consider factors such as functionality, compatibility, and desired outcomes.

Evaluate Available Options

Research and evaluate the available options for the additional portion. Compare features, specifications, and reviews to determine which option best meets your needs.

Consider Budget Constraints

Ensure that the selected additional portion aligns with your budget constraints. Evaluate the cost-effectiveness of each option and prioritize based on value and affordability.

Assess Compatibility

Ensure that the chosen additional portion is compatible with existing systems or components. Compatibility issues can lead to inefficiencies and delays, so thorough assessment is crucial.

Seek Expert Advice

If you’re uncertain about the selection process or the suitability of specific options, seek advice from experts or professionals in the field. Their insights and expertise can help you make informed decisions.

Conclusion

In conclusion, granite can indeed be crushed using specialized portable crusher plant and techniques. Crushed granite finds numerous applications in construction, landscaping, and infrastructure projects, thanks to its durability and aesthetic appeal.

Whether you’re looking to enhance your landscaping or undertake a construction project, crushed granite offers a versatile and durable solution.

Selecting an additional portion requires careful consideration of specific needs, available options, budget constraints, compatibility, and expert advice. By following these notes, you can make informed decisions that contribute to the success of your project or task.