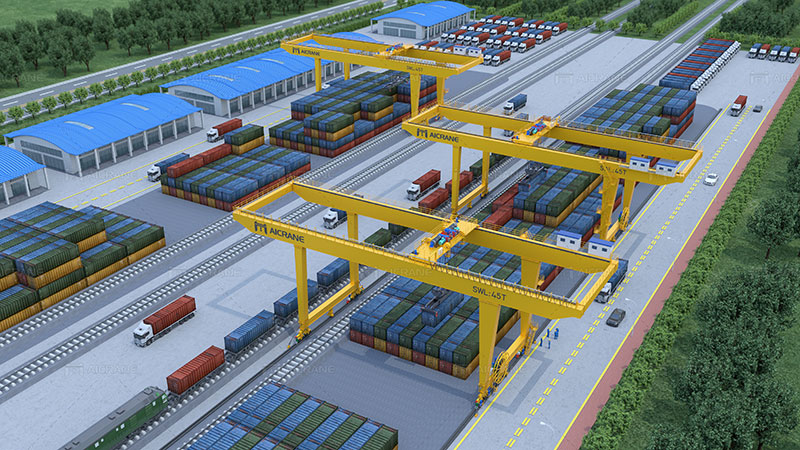

Rail mounted gantry cranes (RMG cranes) play a crucial role in the efficient handling of cargo and containers at ports, rail yards, and intermodal terminals. These sophisticated machines are essential for modern logistics and transportation industries. As with any industrial equipment, the price of an RMG crane is determined by various factors. In this article, we will explore the key aspects that affect the rail mounted gantry crane price.

Capacity and Size

The most obvious factor influencing the rail mounted gantry crane price is its lifting capacity and size. Cranes with higher lifting capacities and larger spans are generally more expensive due to the additional materials, engineering, and manufacturing requirements to support the increased load. An RMG crane designed to handle heavier containers and cargo will naturally cost more than a smaller and less powerful model.

Span and Clearance Height

The span and clearance height of an RMG crane are important considerations based on the specific operational requirements of the facility. A wider span and higher clearance height allow the crane to cover a larger area and accommodate taller stacks of containers. However, these design enhancements can increase the overall cost of the crane.

Automation and Technology

Automation and advanced technology have become significant drivers of productivity and efficiency in the material handling industry. The integration of automation features such as remote control, computerized systems, and data analytics can substantially impact the price of an RMG crane. Fully automated RMG cranes, though costly, offer advantages in terms of optimized operations and reduced labor requirements.

Manufacturer and Brand Reputation

The reputation and brand recognition of the manufacturer also play a crucial role in determining the price of an RMG container gantry crane. Well-established and reputable manufacturers are often perceived as producing higher quality and reliable equipment, which may justify a higher price tag. Customers are often willing to pay a premium for a product with a proven track record of performance and durability.

Material and Construction Quality

The quality of materials used in the construction of an RMG crane can significantly influence its price. Cranes built with high-grade materials are likely to have superior structural integrity, longer service life, and better resistance to wear and tear. While such materials may increase the initial cost, they can lead to reduced maintenance expenses in the long run.

Power Supply and Energy Efficiency

The power supply required for the operation of an RMG crane and its energy efficiency are crucial considerations, especially for long-term cost savings. Cranes equipped with energy-efficient technologies, such as regenerative drives and frequency converters, might have a higher upfront cost but can significantly reduce energy consumption and operational expenses over time.

Geographic Location and Local Regulations

The geographic location of the installation site can also impact the price of an RMG crane. Transportation costs, import/export duties, and taxes can vary depending on the country or region. Additionally, compliance with local regulations and safety standards might necessitate specific modifications or customizations, which can affect the final price.

After-Sales Support and Services

The level of after-sales support and services offered by the manufacturer or supplier can influence the overall cost of the RMG crane. Comprehensive warranty packages, maintenance contracts, and readily available spare parts can add value to the purchase and may justify a higher price point.

Market Demand and Economic Conditions

The state of the market and prevailing economic conditions can also have an impact on the price of gantry cranes. During periods of high demand and economic prosperity, prices may be driven up due to increased competition and limited supply. Conversely, during economic downturns, manufacturers may offer competitive pricing to stimulate demand.

Conclusion

The price of a rail mounted gantry crane is influenced by a multitude of factors, ranging from technical specifications and material quality to automation capabilities and market conditions. When considering the purchase of an RMG crane, it is essential for buyers to carefully assess their operational needs, budget constraints, and long-term goals. By understanding the various factors influencing the price, decision-makers can make informed choices to acquire the most suitable RMG crane for their specific requirements.