For contractors and project managers in the road construction industry, maximizing asphalt plant uptime is critical. Every minute of downtime translates directly into lost productivity, delayed schedules, and increased costs. In continuous road projects, where steady asphalt supply is essential, maintaining consistent plant operation is even more crucial. Fortunately, with advancements in technology, IoT monitoring offers a promising solution to boost asphalt plant uptime significantly.

Why Asphalt Plant Uptime Matters in Road Construction

Before diving into the benefits of IoT monitoring, it’s important to understand why uptime is such a pivotal factor. Asphalt plant for sale is the backbone of road paving operations. When a plant runs smoothly, trucks receive hot mix asphalt on time, paving crews work efficiently, and projects stay on track. However, unplanned stoppages due to equipment failure, material shortages, or human error can disrupt the entire workflow.

Typically, asphalt plants operate with an uptime ranging from 85% to 95%, depending on maintenance, management, and operating conditions. Even a 5% increase in uptime can translate into hundreds of extra production hours annually for large projects. Thus, finding effective ways to monitor and reduce downtime is a top priority for contractors aiming to improve profitability and meet project deadlines.

How IoT Monitoring Transforms Asphalt Plant Operations

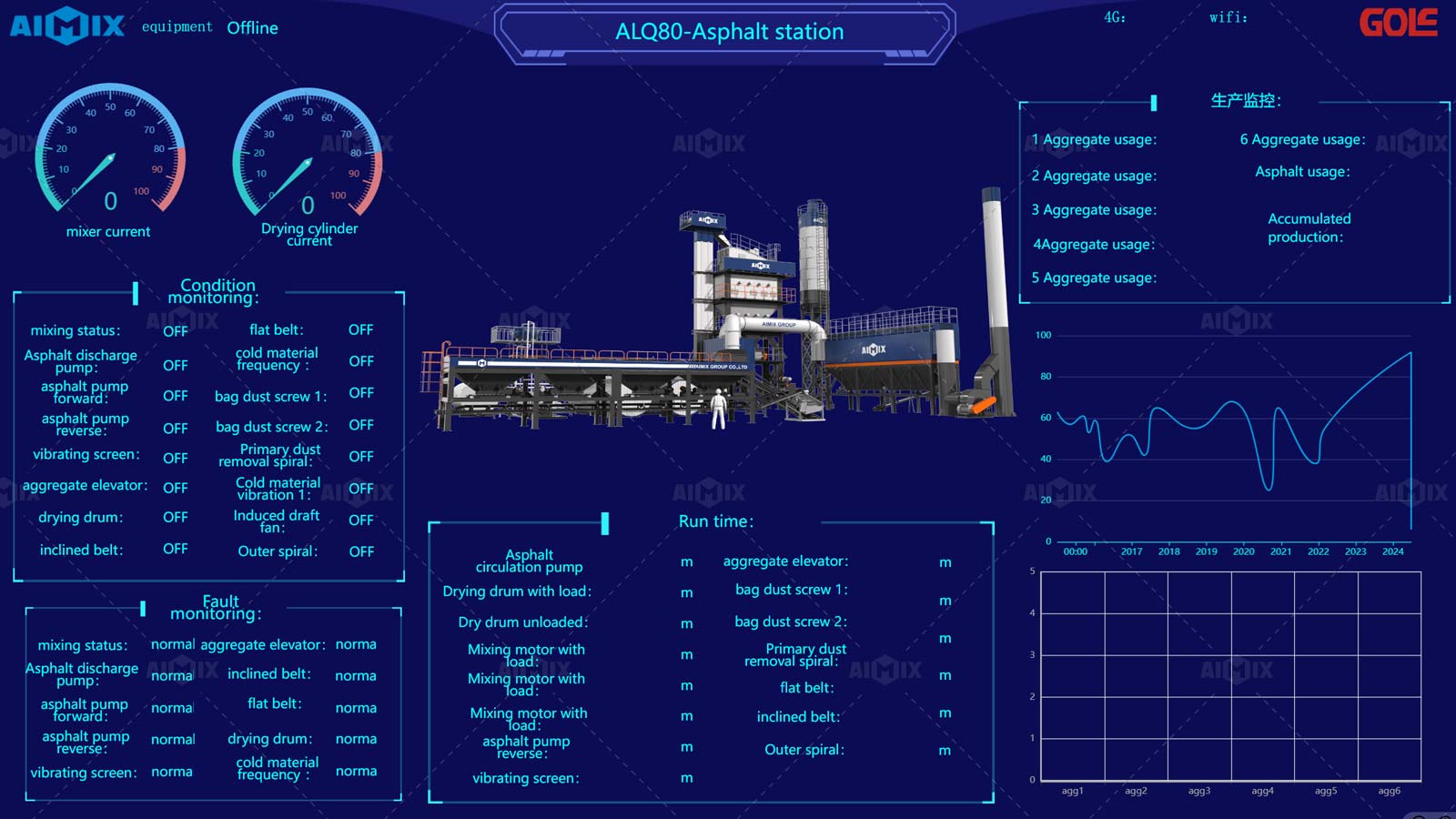

Internet of Things (IoT) technology integrates sensors, data analytics, and remote control systems into asphalt plants. These smart systems provide real-time visibility into every critical component—from temperature controls and fuel consumption to conveyor belts and mixers. As a result, operators gain actionable insights to detect issues early and prevent breakdowns.

Moreover, IoT systems enable predictive maintenance by analyzing trends and forecasting when equipment might fail. Instead of reacting to sudden breakdowns, teams can schedule timely repairs during planned downtime, minimizing unexpected disruptions.

Key Benefits of IoT Monitoring on Asphalt Plant Uptime

- Real-time Alerts: Instant notifications of abnormal conditions allow quick intervention.

- Predictive Maintenance: Data-driven scheduling reduces emergency repairs.

- Remote Monitoring: Managers can oversee plant status from anywhere, ensuring rapid decision-making.

- Optimized Resource Use: Monitoring fuel and material usage helps improve efficiency.

- Data-Driven Decisions: Historical data supports continuous improvement efforts.

Together, these features dramatically reduce unplanned downtime and improve overall hot asphalt mixing plant availability.

Quantifying Uptime Improvement with IoT in Continuous Road Projects

In real-world applications, many contractors report uptime improvements ranging from 5% to 12% after implementing IoT monitoring systems on their asphalt plants. For example, a typical asphalt plant running 2,000 hours annually with a 90% uptime achieves 1,800 productive hours. Increasing uptime by just 7% raises productive time to 1,940 hours — an additional 140 hours of operation that can directly boost output and revenue.

Continuous road projects benefit even more from this improvement. Since paving requires consistent material supply, IoT-enabled uptime reduction helps maintain steady progress and prevents costly delays caused by plant stoppages. Additionally, better equipment health and operational efficiency reduce repair costs and extend the plant’s service life.

Case Example: A Mid-Sized Contractor

A mid-sized contractor in Southeast Asia recently installed an IoT monitoring system on their 80 TPH batch mix asphalt plant. Within six months, they reduced unexpected breakdowns by 30% and improved overall uptime by approximately 8%. The results included faster project completion and lower maintenance expenses—outcomes that strengthened their competitive edge in the local market.

Challenges and Considerations When Implementing IoT

Despite its advantages, IoT implementation requires careful planning. Contractors should consider:

- Initial Investment: Costs for hardware, software, and training must be budgeted.

- Data Security: Protecting sensitive operational data is critical.

- Integration: Systems must be compatible with existing plant equipment.

- Operator Training: Staff must learn to interpret data and respond effectively.

However, the long-term return on investment typically outweighs these challenges, especially for large-scale continuous road projects.

Conclusion: Boost Asphalt Plant Uptime with IoT Monitoring

From a contractor’s perspective, increasing asphalt plant uptime by even a small percentage can yield significant gains in productivity and cost savings. IoT monitoring equips road construction teams with the tools to detect problems early, schedule predictive maintenance, and optimize operations in real time. This leads to fewer unplanned stoppages and smoother project execution.

If your continuous road projects demand higher efficiency and reliability, investing in IoT monitoring is a smart step forward. At AIMIX, we, as an outstanding asphalt mixing plant supplier, specialize in providing advanced IoT solutions tailored for asphalt plants. Our systems help you maximize uptime, control costs, and deliver road projects on time. Contact us today to learn how we can support your success with smart asphalt plant technology.