Marine hydraulic winches have long been recognized for their robust capabilities in various maritime applications, from anchoring and towing to lifting and mooring. One remarkable use that showcases the versatility of hydraulic winches is their integration into dynamic positioning systems for vessels. Dynamic positioning (DP) is a crucial technology employed in offshore operations, enabling vessels to maintain a precise position without traditional anchoring. In this article, we explore the feasibility and advantages of utilizing a marine hydraulic winch for dynamic positioning, shedding light on the technological intricacies that make this integration possible.

Understanding Dynamic Positioning

Dynamic positioning is a technology employed in vessels to automatically maintain their position and heading using a combination of thrusters, sensors, and sophisticated control systems. This capability is particularly essential in offshore industries such as oil and gas exploration, where maintaining a stationary position is paramount for safe and efficient operations. Unlike traditional anchoring, dynamic positioning allows vessels to hold their position in varying sea conditions and even in the absence of a fixed point to anchor to.

The Role of Hydraulic Winches in Dynamic Positioning

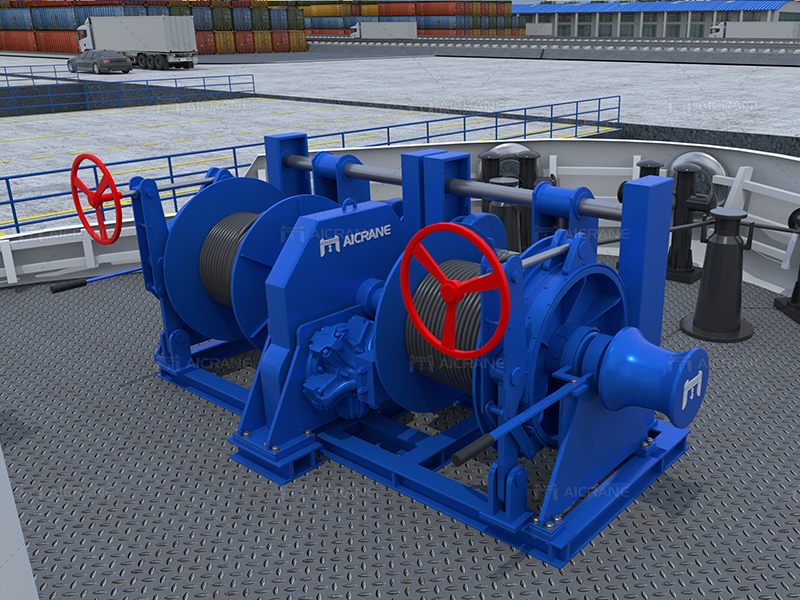

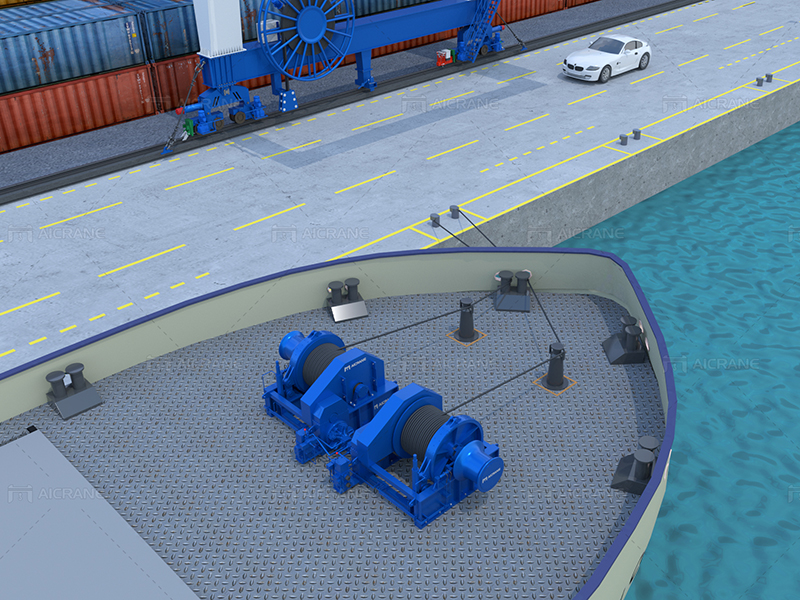

Hydraulic winches play a crucial role in the dynamic positioning system of a vessel, contributing to the overall station-keeping capability. These marine hydraulic winches are often employed to control and adjust the length of mooring lines, aiding in the precise positioning of the vessel. The hydraulic power utilized by these winches ensures a reliable and consistent force, allowing for quick and accurate adjustments to the tension in the mooring lines.

Key Components of a Dynamic Positioning System

Hydraulic Winches: Hydraulic winches used in dynamic positioning systems are designed to handle the specific requirements of maintaining position in dynamic environments. These winches are equipped with high-capacity drums and powerful hydraulic motors to swiftly and precisely adjust the tension of the mooring lines.

Thrusters: Thrusters are propulsion units mounted on the vessel that can be rotated in any direction. They work in tandem with the hydraulic winches to maintain the vessel’s position. The dynamic positioning system calculates the required thrust and directs the thrusters accordingly, ensuring the vessel stays on course.

Positioning Sensors: GPS receivers, gyrocompasses, and other positioning sensors provide real-time data about the vessel’s position and orientation. This information is fed into the dynamic positioning control system, which then adjusts the thrusters and winches to maintain the desired position.

Control System: The dynamic positioning control system is the brain of the operation. It processes data from positioning sensors, environmental sensors, and user inputs to calculate the necessary adjustments to maintain the vessel’s position. The control system communicates with hydraulic winches to ensure precise control over mooring lines.

Advantages of Hydraulic Winches in Dynamic Positioning

Power and Reliability: Hydraulic winches offer high power and torque, providing the force needed to handle mooring lines in varying sea conditions. Their reliability is crucial for the continuous and precise adjustments required in dynamic positioning.

Quick Response: The hydraulic system allows for quick response times in adjusting the tension of mooring lines. This is essential for swiftly adapting to changes in environmental conditions and maintaining the vessel’s position without delay.

Adaptability to Harsh Environments: Hydraulic winches are known for their resilience in harsh marine environments. The robust construction and resistance to corrosion make them well-suited for offshore operations where vessels are exposed to challenging weather conditions and saltwater.

Load Handling Capacity: Dynamic positioning may involve handling significant loads, especially in offshore industries. Hydraulic winches, with their high load-handling capacity, are capable of managing the forces exerted on mooring lines during dynamic positioning maneuvers.

Integration with Vessel’s Hydraulic System: Many vessels are already equipped with hydraulic systems for various functions. The integration of hydraulic winches into the existing hydraulic system simplifies installation and ensures seamless compatibility.

Case Studies

Several vessels in the offshore industry have successfully integrated hydraulic winches into their dynamic positioning systems, showcasing the practical implementation and benefits of this technology.

Offshore Support Vessels (OSVs): Offshore Support Vessels, often used in the oil and gas industry, utilize dynamic positioning systems with hydraulic winches to assist in various operations, including platform supply, towing, and anchor handling.

Research Vessels: Research vessels engaged in scientific exploration and data collection in remote maritime areas benefit from dynamic positioning systems. Hydraulic winches play a crucial role in maintaining station-keeping positions during research activities.

Challenges and Considerations

While the integration of hydraulic winches into dynamic positioning systems offers numerous advantages, it is essential to consider potential challenges:

Maintenance Requirements: Regular maintenance of hydraulic winches is crucial to ensure their continuous and reliable operation. Proper lubrication, inspection of hydraulic components, and adherence to manufacturer-recommended maintenance schedules are essential.

System Redundancy: Given the critical nature of dynamic positioning in offshore operations, systems often incorporate redundancy to mitigate the risk of failure. This includes redundant hydraulic systems, thrusters, and control units to ensure system reliability.

Environmental Impact: Offshore operations can expose vessels and equipment to harsh environmental conditions. Hydraulic winches must be designed to withstand corrosion and other environmental challenges to maintain their functionality over time.

Conclusion

The integration of marine hydraulic winches into dynamic positioning systems has revolutionized the way vessels operate in challenging offshore environments. These systems provide a level of precision and control that is crucial for safety, efficiency, and operational success in industries such as oil and gas, research, and maritime logistics. As technology continues to advance, the marriage of marine winches and dynamic positioning systems is likely to play an increasingly vital role in the future of maritime operations.